Good day everyone. Today is Thanksgiving and you know what that means: turkey time. Make sure to enjoy the experience with friends and family. Don’t forget to burn off the turkey later on through running (or any other forms of exercise). 😉 Enjoy it and again, we wish you all a Happy Thanksgiving.

Category: Company

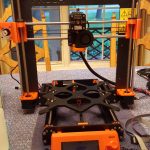

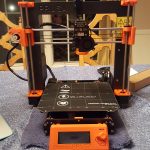

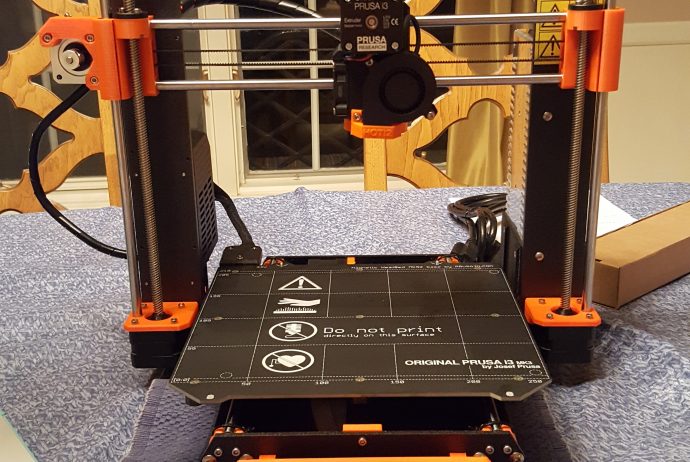

We got a Prusa i3 MK3 3D printer

While I was visiting my family in Texas during Thanksgiving break, I suggested the idea of purchasing a 3D printer to 3D print parts for prototype backpacks rather than always purchasing the parts (strap adjustors for example). That way we can save money. I looked up five different 3D printers and compared one another their features. In the end, I selected the Original Prusa i3 MK3 kit for its size, sensors, and power panic feature. I made the purchase on May 17th, 2018, and the kit arrived on July 25th, 2018.

On July 29th, I began assembling the 3D printer. I finished assembling it on July 18th. Now the average amount of time to assemble the kit, according to the company, was 8 hours. For me to assemble the kit, it took me between 8 to 9 hours. Plus the 2 hours to calibrate the print (had to redo a couple of times with a few adjustments to one of the sensors). The hardest part was assembling the extruder (E-axis). You can see the assembly and calibration below:

- The package has arrived

- Opening the package

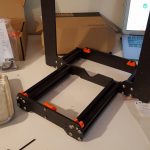

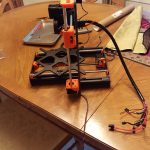

- Assembling the y-axis (part 1)

- Assembling the y-axis (part 2)

- Assembling the y-axis (part 3)

- Assembling the y-axis (part 4)

- Assembling the y-axis (part 5)

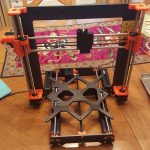

- Assembling the x-axis (part 1)

- Assembling the x-axis (part 2)

- Assembling the x-axis (part 3)

- Assembling the x-axis (part 4)

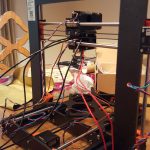

- Assembling the e-axis (part 1)

- Assembling the e-axis (part 2)

- Assembling the e-axis (part 3)

- Assembling the e-axis (part 4)

- Assembling the e-axis (part 5)

- Assembling the e-axis (part 6)

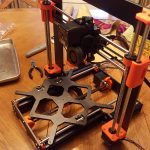

- Electronic assembly

- Electronic assembly

- Electronic assembly

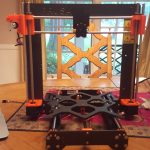

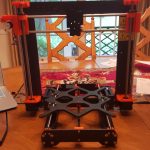

- Final product (part 1)

- Final product (part 2)

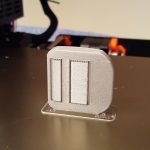

Now was it worth the time to assemble this printer? My answer is… a bit fat YES!!! When I got it printing, it functions smoothly… like butter. Very easy to operate, very relaxing to listen to, and very pleasant to watch. You can see the first couple prints below:

- First print – Prusa Logo

- Second print – Batman symbol

- Printing with supports.

- The left one was printed without supports. The right one was printed with supports.

With it operating, we can now not worry about purchasing strap adjustors, and other printable parts every time we make a prototype. This is just the beginning of whats to come. We are looking forward to it.

Pick’n Run Shirts for the Holidays

For the holidays this year, Martin and I got Pick’n Run shirts as our gifts 🙂

Continue Reading →

Pick’n Run using The Alley Makerspace

Being a Michigan Tech student has many benefits. One of them is being able to access and coach workshops promote creating at the Alley Makerspace. The Alley Makerspace is a place run by Michigan Tech students to allow students, faculty, and staff to work on building things that inspire them or are part of their course work at the university. Continue Reading →

The Process of the 1st Pick’n Run Backpack

It has been 7 months since the first cut on the fabric has begun. Progress is coming along. The first two due dates has past: April 15 2015 and June 30 2015. Measurements had to be precise, sewing took patients (both hand and machine), and ideas came flowing in from my dad, friends, and my understanding. I am adding new accessories to the bag bit-by-bit. Very soon, I will start all over for the second prototype with new materials to use and different ideas to solve flaws of the current bag.

Here are the April 15 requirements with color code of completion:

(Green for meeting requirement, Yellow for half meeting requirement, and Red for not meeting requirement)

–Tight, doesn’t move when running

–Easy to pick-up trash

–Easy to empty trash

–With replaceable linear

Here are a few pictures of the first test run (sorry for not having pictures of the making):

With one of the requirements not met, I worked on the linear with an elastic mechanism that allows runners/walkers/trail runners to pull the linear out to put trash in and let the elastic straps pull the linear back in. It was all thanks to a friend of mine and John’s (my father) who suggested the idea. I founded a problem that I made while making the mechanism: the linear will not keep its form and the straps are not pulling back the linear to its original placement. There are other flaws that I need to fix that has to do with the bag’s structure. So far, I do have a few ideas to fix that.

Now, here are the June 30 requirements:

–Comfortable to run with; light

–Easy to put on and take off

Below are the photos of the accessories:

- The linear

- The linear

- Holes to make the linear movable in and out

- The elastic strap to pull the linear

- The other elastic strap

- Hooks to connect with the elastic straps

- A

- The shoulder cushion

- My stick work

- Strap adjuster on the cushion

- The front view of the shoulder and waist straps

- Me wearing the bag

As you can see of my work, I ran into problems in making the elastic mechanism work. One of them is making the elastic straps strong enough to pull the linear back and the other is making sure that putting and taking off the bag would be easy with the cushion.

As I said before, I found some ways to fix those flaws. Since the next due date is August 31, it is a perfect time to start all over and make the next prototype better. I will keep you all updated on the bag progress along the way. Thank you for staying in tune and keep on cleaning the world through running.

Pitched at Pitch Zoo

Martin recently pitched the Pick’n Run concept that we have been working on for the past couple of years. He pitched it at Pitch Zoo in Kalamazoo on Monday, June 3rd. He received good feedback from others in the startup community. Two others pitched their ideas to the group and received feedback: http://www.pitchzoo.com/?p=233